Industrial and Hazardous-Duty Bottled-Water Coolers

DMC manufactures the first line of truly industrial bottled-water coolers. Made of 316L stainless steel, all are designed specifically for corrosive, dusty, hot, humid, and, when necessary, hazardous (explosive) locations.

These Are Standard Features, Not Options:

- To resist corrosion and damage, all cabinets made with 18-gauge stainless-steel (type 316L)

- Anti-corrosion coating baked onto all condensers and tubing

- Full rated cooling capacity up to 131°F (55°C) — not just up to the normal 95°F (35°C) — without modification or electronic controls

- Mechanical controls only — eliminates vulnerability of electronics and their high cost to repair

- All controls protected in NEMA 4 (IP65) or NEMA 4/7/9 enclosure. All complete units also meet the NEMA 4 or NEMA 4/7/9 standards

- Units have extra-large condensers to provide cooling at high altitudes and at high ambient temperatures

- Corrosion-resistant valve for filling cups from an extra-large reserve of cold water

- All units available modified for hazardous locations (“explosion-proof”) — Divisions/Zones 1 or 2

- Energy efficient at high ambient temperatures and under other harsh conditions, as well as at temperatures below 95°F (35°C)

- Accepts all standard-sized bottles

- Maintenance facilitated by refrigerant access valves and filter-dryer

- ADA compliant

- 115/60/1 or 220-240/50-60/1

Hazardous (Explosive) Locations:

When specified, DMC makes units suitable for hazardous-duty (“explosion-proof” or “flame-proof”) conditions.

We use UL-recognized hazardous-duty compressors appropriate for the classification of the area.

DMC offers bottled-water coolers suitable for use in areas classified as any of the following types of locations: NEC Classes I, II, or III, Groups B, C, D, E, F or G, and Division/Zone 2 or 1 and IEC Classes I, IIA, IIB, and IIC Zones 1 and 2. The units will also be temperature-coded T3B.

DMC seals the coolers in the factory for fast and easy installation, and they retain the same corrosion resistance and other harsh-duty features as DMC's standard coolers.

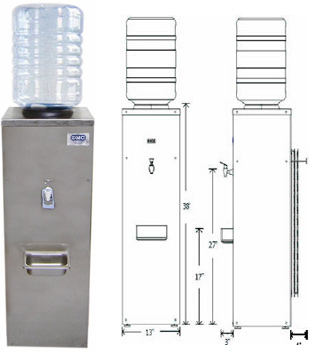

Specifications:

Cabinet: All corrosion-resistant stainless steel type-316L, inside and outside including interior shelves, mountings and drip basin. Satin finish on all exterior surfaces for an attractive and easily-cleaned lustrous appearance. Bottle-support ring made of durable and corrosion-resistant polypropylene.

Controls: Protected from environment by installation inside NEMA 4 (IP65) or NEMA 4/7/9 enclosure.

Valves: Self-closing, no-drip. Made from durable and corrosion-resistant polypropylene.

Cold Water Reservoir: Flat-bottom stainless steel basin with approximately 2-1/2 quarts (2.4 liters) useable capacity and polypropylene fittings. Corrosion-protected copper evaporator coil is wrapped around reservoir, insulated with closed-cell elastomer.

Corrosion Protection: Capillary tube, filter-dryer, two access valves and all other metal tubing protected with either a special epoxy coating (e-coat) with near-zero porosity applied electrostatically and baked or with special enamel paint to protect them from acidic and caustic corrosion.

Condenser: Three rows deep, sized for high ambient temperatures and high altitudes, and protected against acidic and other corrosion with a special epoxy coating (e-coat) with near-zero porosity applied electrostatically and baked.

Compressor: Andover Protection Systems’ Model EEG (for 115/60/1) or APS Model EEJ (220-240/50-60/1). These compressors are specifically designed for and recognized by UL (Underwriters Laboratories) for use in hazardous (“explosive”) areas, even those requiring explosion-proof or flameproof equipment.

Capacity:

Rated Capacity - At water and air temperature of 131° F (55°C) — lower 1/2 gallon per hour of water from

131°F (55°C) to 50°F (10°C) — Note: 131°F water will scald skin; therefore, chiller must lower the water

Capacity at ARI standard conditions - At water and air temperature of 90°F (32.2°C)—lower 0.9 gallons

per hour of water from 90°F (32.2°C) to 50°F (10°C) — (produce 50% more cold water than standard units).

A.D.A.: Overall, the coolers comply with the requirements of the ADA specification 4.15.2-4 ![]()

Shipping Dimensions: Approximately 73 lbs. and 8.6 cubic feet.

Frequent Users of DMC Industrial Coolers in Tough Applications That Require Cold, Safe Drinking Water, Especially If Conditions Are Harsh or Hazardous:

- Airplane Hangers

- Alcohol Extract Plants

- Cement and Lime Plants

- Chemical and Gas Plants

- Coal and Coke Plants

- Corn-Alcohol Refineries

- Dry-Cleaners and Dyers

- Explosives and Munitions Manufacturers

- Fertilizer Plants

- Flour and Feed Mills

- Fragrance and Extract Plants

- Fuel Storage and Handlers

- Grain Elevators

- Guard Buildings

- Hazardous-Goods Storage Facilities

- Hospitals

- Laboratories

- Land Fills

- Recycling Plants

- Mining

- Munitions Handling and Storage

- Nuclear Power Plants

- Offshore Oil-Drilling Platforms

- Oil Refineries

- Painting and Solvents

- Paper Manufacturing

- Pharmaceutical Plants

- Refueling/Loading Facilities

- Ships, Civilian and Military

- Tankers

- Textile Plants

- Vehicle Air-Bag Makers

- Waste-Treatment and Sewer Plants